Description

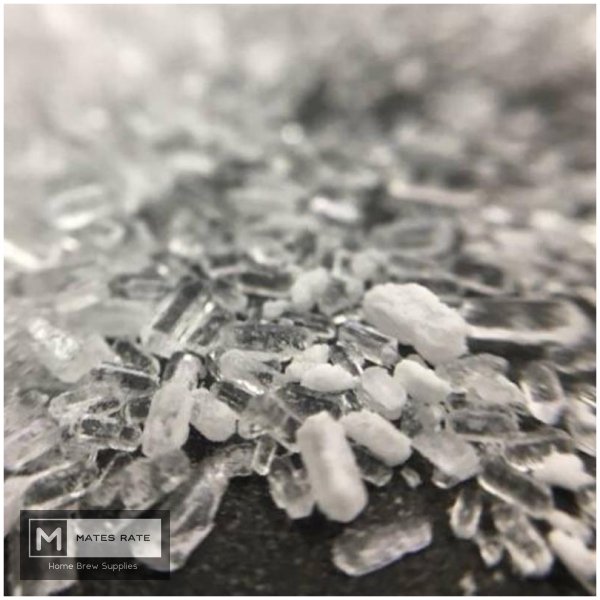

Winy High Purity Potassium Metabisulphite is commonly used in must and wine for its antioxidant, anti-oxidase and antimicrobial agent. It increases polyphenols extraction. Potassium Metabisulphite powder is a substitute for and the main ingredient in Campden Tablets.

Potassium Metabisulphite can also be used during low oxygen brewing processes.

Dosage:

0.8-1.2 g/hL in brewing water to remove chlorine,

10-15 g/hL in the mash to scavenge oxygen during low oxygen brewing processes.

1.0-1.5 g/hL in the sparge water to scavenge oxygen during low oxygen brewing processes.

10-30 g/hL in must according to grape conditions.

2-5 g/hL in wine, at clarification, racking or after filtration.

10-15 g/hL to preserve sweet wines.

1g of Potassium Metabisulphite releases approximately 0.56g of S02.

Warning: For maximum dosages, refer to current applicable laws.

Instructions for Use:

Disolve in a small amount of water, juice or wine and add to the must or wine to be treated.

Storage:

Sealed Package: keep the product in a fresh, dry well ventilated area. Opened Package: carefully reseal the package and keep as above indicated. Hygroscopic product.

Pack and Pack Size:

- 100g net weight plastic bag

Health and Safety Warning:

E 224 Pure Potassium Metabisulphite K2S2O5

C.A.S. number 16731-55-8

DANGER:

-

Causes serious eye damage

-

Wear eye protection / face protection: wear eye glasses with side protection.

-

IF IN EYES: Rinse cautiously with water for several minutes.

-

Remove contact lenses, if present and easy to do.

-

Continue rinsing.

-

Immediately call a doctor / physician.

Contact with acids liberates toxic gas.

Used Barrel Storage, Maintenance and Preparation:

The holding solution is prepared using 1 tsp of citric acid and 1.5 tsp of potassium metabisulfite for each gallon (4 L) of barrel volume. For example, for a 15-gallon (57 L) barrel, use 15 tsp of citric acid and 23 tsp of potassium metabisulfite. (Note: 3 tsp = 1 tbsp) Dissolve these in one gallon of hot water.

Fill the barrel two-thirds with water, add the holding solution, top up the barrel with cool water, and bung the barrel. Top up the barrel with a holding solution once a month to replace solution lost by evaporation and absorption into the wood. The barrel can be stored indefinitely without the risk of spoilage.

During storage, rotate the barrel 45° in either direction every time you top up to keep the bung area soaked. This will prevent the bung area from drying out and protect it from spoilage organism growth. Caution: The sulfur-citric holding solution will etch a concrete floor. Rinse the floor with water to prevent this.

Used barrels require no special preparation beyond a simple water rinse, if desired, when transferring wine out and in immediately. If the barrel has been stored with a holding solution, drain the barrel and rinse it thoroughly with clean water before transferring wine into it.

Reviews

There are no reviews yet.